Domestic Water Disinfection Systems

Domestic Water Treatment: An agnostic approach to healthy water

The Challenge

The water flowing into your building from the municipality is treated with disinfectant to ensure that bacteria and other microorganisms are destroyed, and that healthy water comes out of the tap. The flow of water throughout the municipal systems is typically fast, as the delivery is going to so many consumers. Water use at each building, however, isn’t always enough to keep the water flowing and the levels of disinfectant high enough to keep the bugs at bay.

Building owners rely on secondary disinfection systems and procedures to reduce the risk of microbiological growth when chlorine or other disinfection chemicals from the municipality dissipate. Supplementing with another treatment method keeps building water clean and their people healthy.

Secondary disinfection systems are a critical piece of active water management that ensure your ASHRAE 188 Water Management Program meets CDC recommendations and any requirements set forth by accreditation committees or governing bodies.

Our agnostic approach to secondary disinfection ensures that Earthwise clients have access to the right fit disinfection program for their needs. Our work in hospitals, universities, data centers, manufacturers and residential high-rises shows the depth and breadth of innovative disinfection technologies we represent – all with the health of your patrons and staff as the top priority.

Some example systems we install and service:

Chlorine Dosing Systems

First used over a century ago, and still used today, chlorine disinfection is a chemical disinfection method that uses various types of chlorine or chlorine-containing substances for the oxidation and disinfection of what will be the potable water source.

A leading advantage of chlorination is that it has proven effective against bacteria and viruses.

The chlorination process is also easy to implement compared to other water treatment methods. It is an effective method in water emergency situations as it can eliminate an overload of pathogens relatively quickly. An emergency water situation can be anything from a filter breakdown, burst pipe, or construction that affects the water coming into your building system.

Chlorine dosing is a proven method of controlling microbiological growth

Unlike some of the other disinfection methods like ozonation and ultraviolet radiation, chlorination provides a residual to reduce the chance of pathogen regrowth in water storage tanks or within the water distribution system.

Drawbacks to chlorine dosing include the handling and transport of chemicals to feed the dosing system. Liquid chemical transport is costly, and chlorine loses efficacy quickly so it can’t be stored for a long time. Handling liquid chlorine also poses a significant risk to operators, increasing building owner liability.

Feeding chlorine requires constant monitoring – too little chlorine risks biological growth, and too much chlorine will lead to corrosion in the system.

Chlorine feed is effective in cold water systems, while hot water systems will consume chlorine too quickly to prevent biological growth.

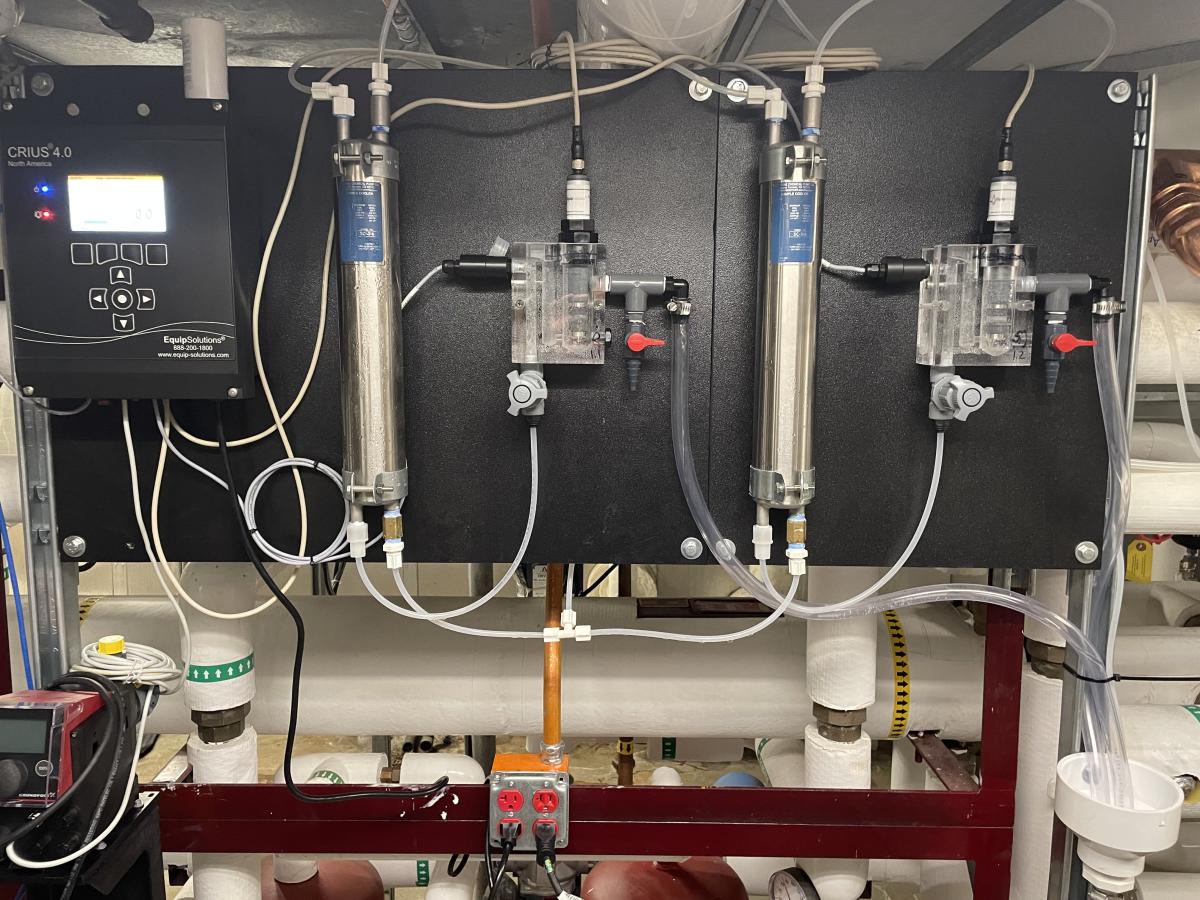

Chlorine Ionization Systems and Mixed Oxidant Systems

On-site mixed oxidant generators and chlorine generators produce chlorine-based disinfectants when a solution of sodium chloride (salt + water) is passed through an electrolytic cell. This process converts the chloride ions present in the solution to sodium hypochlorite.

These mixed oxidant systems also convert some of the oxygen in the water molecule into hydrogen peroxide. This combination of sodium hypochlorite and hydrogen peroxide creates a unique chemistry that has many proven operational benefits in drinking water applications.

On-site oxidant generation eliminates the risks of handling liquid chlorine products, and a significant amount of the shipping costs. A salt supply can easily be stored and handled by operators.

There is a mixed oxidant generator to fit every system size and demand

In an emergency event such as burst pipes or filter breakdown, supplemental disinfection such as additional chlorine would be required to eliminate risk, as the concentration of oxidants generated is not strong enough to quickly eradicate biological growth.

Systems require regular maintenance and monitoring to ensure adequate levels of salt are in the system.

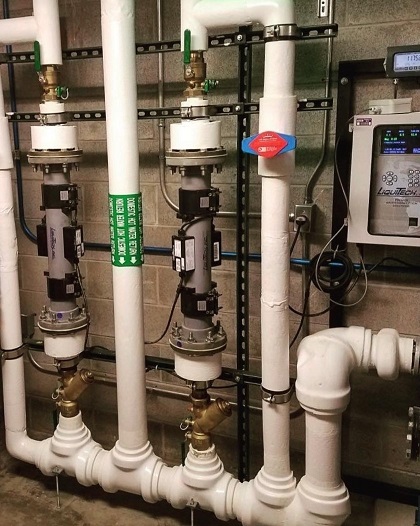

Copper-Silver Ionization

Copper silver ionization is an electrolysis process in which current is applied across copper and silver alloy electrodes. The process releases positively charged ions into the water. These ions bind to the negatively charged cell walls of bacteria causing the protein in the cell wall to break down, rendering the bacteria ineffective.

Copper silver ionization is an effective disinfection process that requires no chemicals, involves no dangerous by-products, and does not use unsafe consumables like chlorine.

Copper silver ionization protects your building by preventing damage to the plumbing infrastructure

This disinfection method is effective at point of entry and in both hot and cold-water temperatures, unlike traditional chemical technologies whose disinfectant rapidly dissipates in hot water environments rendering it ineffective.

These systems require cleaning and maintenance on a regular basis to ensure proper function. Water testing to ensure acceptable levels of copper and silver per EPA limits occur monthly.

Validation

As critical as any secondary disinfection system in place is making sure that it is providing effective biological control through testing. The CDC and Healthcare Infection Control Practices Advisory Committee (HICPAC) offer two ways to validate the efficacy of a Water Management Program

- Performing active clinical surveillance for infections due to Legionella

- Performing environmental sampling for Legionella

As the name implies, active clinical surveillance is for healthcare environments where a patient is already diagnosed with a Legionella-induced pneumonia. Environmental sampling is looking for legionella in the water system through legionella water sampling in an effort to find and eradicate it before it becomes an issue.

At Earthwise, we strongly recommend a more proactive approach to validation of your Water Management Program, using environmental sampling.

Environmental sampling involves testing for the presence of Legionella bacteria throughout the building water systems. This proactive method of validation ensures that the protocol and secondary disinfection methods in place are effectively controlling the growth of biofilm in risky areas.

Legionella test results should be interpreted by ASSE/IAPMO Certified Legionella Safety and Water Management Personnel to determine next steps and the level of risk posed to your building occupants.

When properly interpreted by a trained expert, Legionella test results empower you to understand how to efficiently target areas of your facility and identify risk locations before they cause illness.

Earthwise has partnered with CDC Elite laboratory Special Pathogens Laboratory for independent analysis of our clients Legionella test results. Led by Dr. Janet E. Stout, renowned Legionella expert, SPL helps us to ensure independent third-party validation of our work and yours in ensuring Legionella Control. We then use SPL’s control measures to ensure that in the event of positive test results we are using recommended best practices to mitigate issues uncovered.